SUTRAK Begins Production on Dallas Area Rapid Transit (DART) All Electric HVAC Project |

MARCH 2012 – SUTRAK received the first set of purchase orders to manufacture all-electric ACE rear mount HVAC systems for Dallas Area Rapid Transit's (DART) next generation buses worth $3.9M, with the entire multi-year production order expected to be worth approximately $19M. The DART project represents the first large scale deployment of SUTRAK ACE (Air Conditioning Electric) rear mounted systems. SUTRAK’s ACE Rear Mount systems were given a complete redesign to meet the demanding specification requirements of Dallas Area Rapid Transit. After analyzing the data from proof-of-concept testing conducted during 2004 and 2005, DART chose SUTRAK’s ACE technology for it’s next procurement cycle. In addition to the improvements in performance, reduced maintenance requirements, and enhanced fuel economy benefits promised by SUTRAK’s electric systems, DART took into account their 24 year relationship working with SUTRAK. The company’s proven reliability and oustanding product support gave DART the confidence to incorporate SUTRAK’s electric systems into their new buses. Rear mount HVAC systems were required due to the placement of CNG tanks on the vehicle’s roof. Although aquisition costs for the rear mount electric system is higher than traditional HVAC, the full life cycle cost of the system is expected to produce substantial savings. SUTRAK’s technology demonstrates a reduced parasitic load on the engine resulting in higher fuel efficiency. Coupled with the increased reliability of AC voltage components, the system offers a faster return on investment, and reduced cost of ownership over the life of the product. In addition to cost savings, DART’s ridership will experience consistent temperature comfort with considerably quieter operation from Sutrak’s ACE rear mount system, and the vehicle's compressed natural gas motor. Design improvements over early generation rear mount HVAC systems include higher volume airflow for greater efficiency and reduced noise, and the incorporation of next generation compressor technology for peak efficiency and higher performance. DART’s maintenance technicians will experience lower routine maintenance requirements with the new hermetic compressor—the elimination of the piston driven compressor attached by belt to the engine will result in one of the biggest changes in maintenance practices. |

|

|

SUTRAK Exhibits ACE Technology at APTA Expo 2011 in New Orleans |

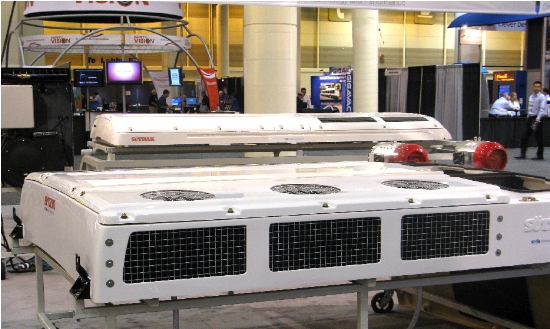

OCTOBER 2011 – Held every three years, the American Public Transportation Association (APTA) EXPO is public transportation’s premier showcase of technology, products and services. This years event featured 750 public transportation-related companies exhibiting products and services across 280,000 square feet of exhibit space to an estimated 17,000+ attendees. Sutrak's All-Electric HVAC systems were on display, and Sutrak was the featured speaker at the Electric HVAC Workshop. |

All New 2013 ACE219G Rear Mount Electric |

Now in production at our headquarters facility is the (Air Conditioning Electric) ACE 219G rear mount HVAC system for Transit buses. Dallas Area Rapid Transit is the first recipient of the improved system on CNG buses built by North American Bus Industries. “During testing, these systems demonstrated the fastest performance pull-down of any HVAC system in the US transit industry with R-134a refrigerant.” It includes a light weight fiber-composite shell that has undergone numerous modifications from the original ACE rear mount system introduced 10 years ago. The result is a 30% increase in airflow while decreasing noise levels that were already lower than traditional 24VDC design HVAC systems. Three phase motors throughout including electric scroll compressor technology from Emerson Climate Technologies are lowering maintenance and operating costs dramatically including up to 50% reduction in parasitic load off the engine. The DART buses are equipped with SUTRAK’s synchronous alternating current generator that is air cooled and belt driven from the main engine. Optimum performance and reliability while saving operating costs. What a great way to start the new year! |

Broward County Transit Expands Fleet |

In Q1 2013, SUTRAK completed another 49 roof mounted electric systems for Broward County Transit diesel and diesel electric buses. Built by North American Bus Industries, these buses integrated SUTRAK’s ACE systems for climate control. “Our ACE systems have been part of the county specifications since 2006 and they were the earliest adopter in the Transit Industry of electric HVAC systems powered by an independent power generation package” says Scott Imamura, VP Sales. In addition to parasitic load savings and related fuel savings, all of the roof mounted systems to date are designed with two refrigerant loops offering true redundancy with balanced cooling to both sides of the vehicle. This is like having two HVAC systems on each vehicle capable of operating at full or half capacity as the conditions require. |

Allison Hybrid Bus Power for Air Conditioning |

MODELS AFFECTED: H 40/50 EP™ Effective April 2013, Allison Transmission, Inc. is pleased to announce the introduction of the High Voltage Distribution Module (HVDM) to provide increased power for accessories such as air conditioning systems. Increased Accessory Power – High Voltage Distribution Module (HVDM) Purpose Up to 30kW of DC power (un-conditioned) to power high voltage electric accessory components via two load channels to: Provide electric power to the Hybrid Beltless Alternator (HBA) Provide electric power to the vehicle’s Electric HVAC System Benefits The HVDM replaces the large electric generators required to run the vehicle Electric Air Conditioner & associated maintenance / repair costs and downtime. The HBA replaces the large belt driven alternator and associated hardware & maintenance costs. Reduction of engine parasitic losses created by large alternators and electric AC generators, belts and belt tension (side loading) on the engine, and a reduction in downtime created by those components due to maintenance and durability issues. Allison has tested the new power equipment with SUTRAK roof and rear mounted ACE (Air Conditioning Electric) systems including operational stability in extreme hot weather testing (Death Valley, CA). |

|

SUTRAK Exhibits ACE Technology at APTA Expo 2014 in Houston |

October 2014: SUTRAK exhibited roof and rear mount electric bus systems known as ACE (Air Conditioning Electric) systems at the 2014 APTA Expo in Houston Texas. On the show floor were 2 samples of power production (generators), 2 rear mounted systems, and 2 roof mounted systems. SUTRAK exhibited a single loop roof mounted system to compliment the dual loop product line. The single loop system gives prospective clients the option of choosing a system based on price rather than the advanced feature set that comes with redundant dual loop systems. SUTRAK was the first manufacturer to offer production HVAC systems to the US Transit market. Systems are designed and available for hybrid Allison and BAE buses, electric bus manufacturers, and traditional fuel vehicles (Diesel and CNG) via SUTRAK’ own power package. |

|

SUTRAK Completes 475 electric (ACE) Units for DART CNG Buses |

February 2015: SUTRAK completes 475 electric (ACE) units for DART CNG buses. SUTRAK has had the honor of providing HVAC systems to Dallas Area Rapid Transit heavy duty bus fleets since the early 1990’s. DART engineering conducted a feasibility study around 2005 regarding electric HVAC design. The results of that study were positive and today, all of DART’s CNG heavy duty buses utilize a belt-driven synchronous generator to power a self-contained rear mount package. These systems began operation in 2013 and have demonstrated their performance capabilities in the hot Dallas summer seasons. The use of Copeland Scroll compressor technology in our HVAC systems offers transit agencies demonstrably improved operational performance, especially at idle.” says Scott Imamura, VP of sales. (System Type: ACE219G). |

SUTRAK Begins Deliveries of Fully Electric Roof Mounted Systems to New Flyer for the Excelsior 60 Foot Bus Model |

March 2015: SUTRAK begins deliveries of fully electric roof mounted systems to New Flyer for the Excelsior 60 foot bus model. SUTRAK is confident that the testing of the system will set an R-134a performance pull down record for the 60-foot bus. The system that is being delivered offers dual compressors in a dual loop and true redundant configuration. This offers max pull down followed by an energy savings setting which essentially maintains bus temperatures with a single compressor setting. Unique to this system is the capability of delivering cooling to both sides of the bus with one or two compressors engaged (interlaced coils). “While there is an additional cost to this configuration, it offers the most energy savings opportunities to the transit agencies. The operation of these systems with R-134a uses approximately 15 HP from the engine for a 40-foot bus. This is a great savings from the 30+ HP a traditional piston driven compressor and alternator will require for HVAC operation. The single compressor operation brings the total parasitic load down to approximately 9 horse power which further reduces peripheral systems loads on the engine” says Dan Van der Hoop, Director of Engineering. SUTRAK first delivered this patented system design in 2006 to New Flyer buses destined for South Florida. 60-foot bus models can expect to use 2X the power requirement for fully electric systems, however this is still substantially lower parasitic load than the operation of a 6 cylinder compressor supporting 2 evaporator packages. |